Clear Automation Announces Completion of Innovative Robo Flex Filler Line

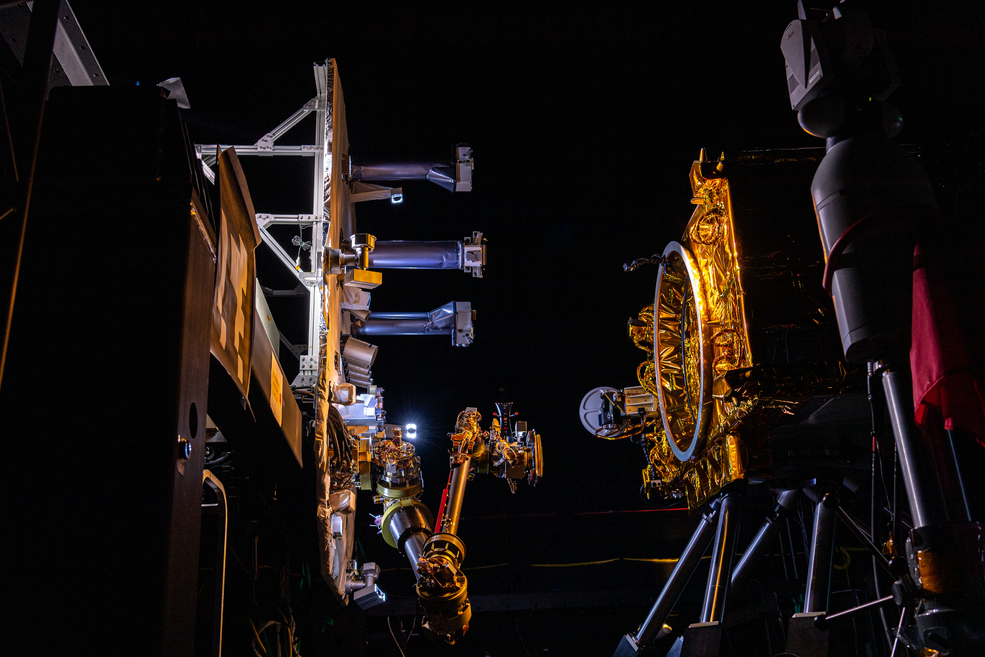

Southington,CT— Clear Automation, a leading robotic systems integrator based in Connecticut, has announced the completion of the Robo Flex Filler Line, an innovative line that will reshape the way Consumer Packaged Goods are packaged.

John DeBlasio, of Clear Automation, said: “Clear Automation equipment excels in a high mix, low volume manufacturing environments —and our robust approach to machine designs creates great value for our client. We are proud to be reaching a renewal phase with our innovative clientele and thank our nationally-recognized clients in industries like cosmetics, personal care, medical devices, pharmaceuticals, consumer packaged goods, consumer and industrial electronics, and industrial processes for their support as we continue to serve their expansive interests and needs.”

The Robo Flex Filler Line is capable of creating 25 million units per year and has a fill range from 30ML to 500ML at an accuracy of +- .025%. The line is capable of handling a wide range of liquid density and container shapes and sizes. It is sanitized in place capable as well as being able to handle flammable liquids. The line is slated to run any of 14 different bottle shapes/sizes with 4 different closures and 12 different pack patterns with change over time of less than 45 min from format to format.

###

About Clear Automation

Clear Automation is a leading robotic systems integrator specializing in flexible industrial automation techniques. Clear Automation’s key strengths include Industrial Robotics, Automation Design, Machine Vision, PLC’s, Line Tracking, and custom PC Applications which are deployed to assemble, inspect, label, laser mark, dispense, and package products. Industries served include Cosmetics, Personal Care Products, Medical Devices, Pharmaceuticals, Automotive, Aviation, Food and Beverage, Consumer Packaged Goods, Consumer and Industrial Electronics, and Industrial Processes.