AIWAYS teams up with world’s best suppliers to develop U5 all-electric SUV

- AIWAYS working with the biggest and best automotive suppliers from Europe

- Combined AIWAYS and supplier expertise helps to enhance driving performance and technical innovation

- Unprecedented level of German industrial expertise at AIWAYS’ €1.73 billion manufacturing facility

Shanghai, 19 June 2020 – AIWAYS, the Shanghai-based personal mobility provider, has confirmed it is working with the biggest and best automotive technology suppliers from Europe to develop the U5 all-electric SUV. The supplier list demonstrates the Chinese startup’s commitment to quality in product development and manufacture.

Suppliers include German giants Robert Bosch, BASF, Benteler Automotive, and Siemens. They have already played important roles in the U5’s engineering and intelligent manufacture, as has Grupo Antolin, Spain’s largest automotive supplier, as well as Autoneum and Georg Fischer, both from Switzerland.

Alexander Klose, Executive VP Overseas Operation at AIWAYS, comments: “We understand that collaboration with the world’s best suppliers will complement our fresh ideas and new way of doing things. It means AIWAYS has the mindset of a startup, backed by many years’ experience. The AIWAYS U5 all-electric SUV offers high quality and innovative, daring technology.”

Supplied by Europe’s best

Robert Bosch, the world’s largest automotive supplier by sales, contributed to the AIWAYS U5’s entertaining and rewarding drive. The U5’s electric power-assisted steering system, developed by Bosch, strikes an ideal balance between practical operation and engaging driver feel.

The all-electric SUV also offers enhanced performance with its rigid, lightweight construction, developed by AIWAYS in partnership with German body-in-white experts Benteler Automotive. The U5’s BIW uses a 52% aluminum and 48% high-strength steel mix, with steel four times stronger than conventional high-strength steel. Pioneering bonding, casting and forming techniques, many provided by Switzerland’s Georg Fischer, help to make the chassis around 50% stiffer than an equivalent steel body, while allowing AIWAYS to create a lighter and more rigid overall construction. The result is a vehicle with a curb weight of 1,750kg – much lighter than other mid-size SUVs despite the 360kg, 63kWh battery, which offers a driving capacity of more than 400km (WLTP) on a single charge.

Innovative technology is truly at the heart of the AIWAYS U5’s cabin, as are quality materials and upholstery from European interior experts Autoneum (Switzerland) and Grupo Antolin (Spain).

German industrial expertise

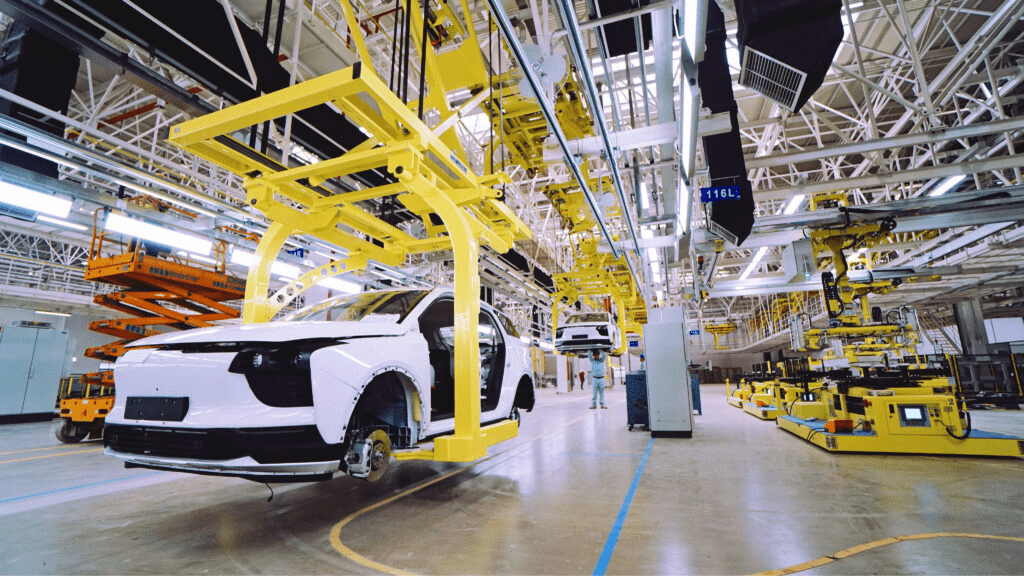

The result of a ¥13.3 billion (€1.73 billion) investment, AIWAYS’ Shangrao production facility is notable for the unprecedented level of German industrial expertise that has gone into the construction and smart manufacturing processes of a Chinese automotive plant.

Engineered to Industry 4.0 standards, AIWAYS has worked with Siemens to develop the ‘two factories, one facility’ concept. This utilizes a highly detailed cloud-based virtual model of the manufacturing facility that communicates online with the physical plant. This allows AIWAYS to monitor every step of the production process remotely, ensuring each vehicle is tracked and accounted for.

AIWAYS has achieved 90% automation at its Shangrao plant, thanks in part to Swiss-Swedish robotics supplier, ABB. In the body shop robots supplied by German automation experts Kuka work individually and in teams, joining chassis components and body panels.

The AIWAYS paint shop, built by the German plant manufacturer Eisenmann, covers 59,073 square meters and forms the interface between the body shop and the assembly shop. It meets the highest efficiency standards and exceeds current environmental protection regulations. The assembly shop is the largest section of the Shangrao site, with 159,269 square meters of assembly lines erected by the German manufacturing specialists Dürr.

Following assembly, the vehicle goes to the battery packing station, in which prefabricated battery cells are joined to form closed storage units. One battery pack consists of 24 modules, each with four lithium-ion cells, developed by the world’s leading battery manufacturer CATL.

Thanks to this unparalleled quality and control offered by the Shangrao plant, AIWAYS can manufacture 150,000 units of the U5 for its Chinese and European customers per annum. The plant can accommodate an increased production capacity to 300,000 cars a year, when the demand arises.

The AIWAYS U5 will be available for private customers in Europe to order this summer, with the first deliveries scheduled for September.