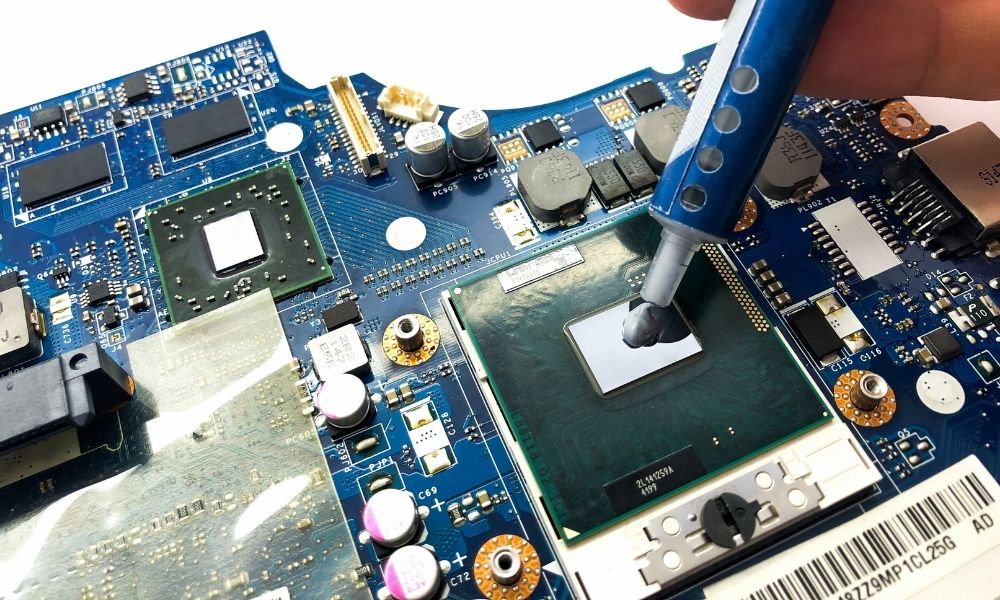

What You Should Consider When Making Quality PCB Designs

Most electronic devices and systems use PCBs to function. The widespread use of PCBs means that people constantly need their own special PCBs for their specific devices. It’s best to create your own design to fulfill all your requirements. You’ll need to keep certain things in mind during the design process of building a PCB, though. Here’s what you should consider when making quality PCB designs.

Board Materials

One of the biggest decisions you’ll need to make is what kind of materials you’re going to use for the PCB board. This decision will affect what your board can handle and the base cost of crafting it. There are stiff materials that most devices use, but one of the top trends in PCB production is using bendable PCB board materials.

Layers

Next, think about how many layers you’re going to include in your PCB. The more layers a PCB has, the more complex it can become. However, it also becomes more expensive and harder to design efficiently. Properly managing the temperature in multi-level PCBs can be challenging, and most devices don’t need complex PCBs to run their functions. So, choose lower layer counts if you want to make it more cost efficient.

Vias and Copper Traces

Most of your design comes from creating the connections between components. The goal is to use as few vias as possible in your design. You also need to handle the copper traces properly, as they control signal integrity.

Part Selection

When you’re selecting your components, there are several things you need to keep in mind outside the exact function of each part. You should choose parts that are in production right now. You should keep in mind the grounding of the components as well.

This is what you should consider when making quality PCB designs. You’ll need to address all these problems when you start your designs.