Applications of Different Types of Ball Screws

Rolled ball screws and ground ball screws are produced in different ways, making each suitable for a different application. How do ball screws work, and what are the applications of different types of ball screws? Read on to find out.

What Is a Ball Screw?

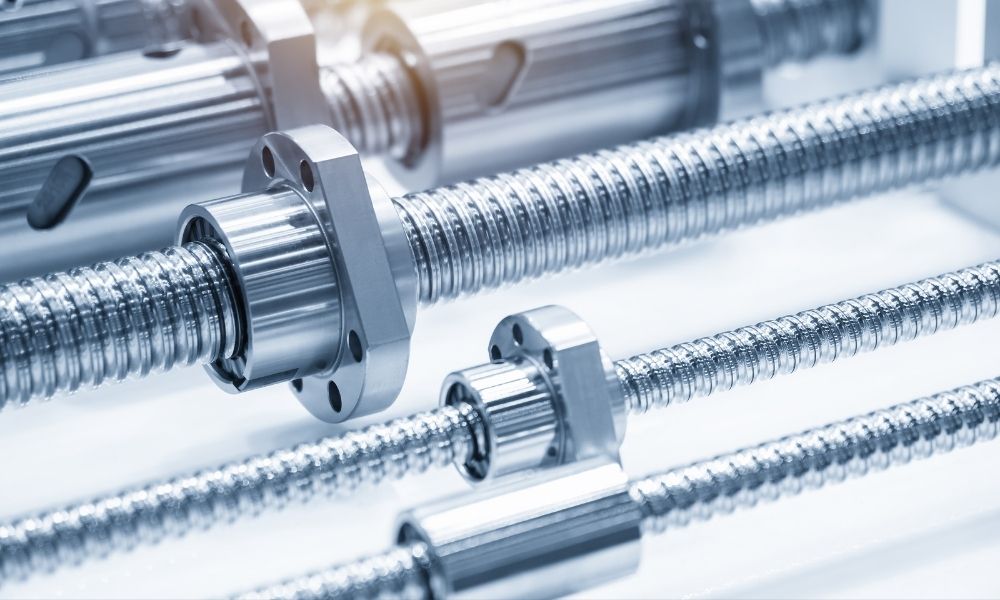

A ball screw is a tool that turns rotational motion into linear motion. It does this using a screw with helical grooves, a nut, and balls (made of steel, ceramic, or plastic). The balls move through the screw, nut, and helical grooves, and this rotation along the grooves produces motion up and down along the screw.

Rolled Ball Screws

Rolled ball screws are the simpler option in terms of manufacturing. The screw shaft is cut to a certain depth and then rolled with a thread rolling machine. This produces an extruded groove over the screw thread. These manufacturing processes lend themselves well to mass production and automation, which allows their final cost to be lower than their ground ball screw counterparts.

Ground Ball Screws

A cylindrical grinding machine repeatedly grinds down ground ball screws to precisely achieve an optimal arc groove shape. This results in no thread groove but a significantly higher accuracy level. Ground ball screws are the best option for high-precision applications but require more time and money to produce. Thankfully, their careful production leads to a longer lifespan than that of rolled ball screws.

Applications

Rolled ball screws are extremely useful in applications that don’t require high levels of precision. You can use them as actuators or even in pick-and-place devices. Ground ball screws, however, are the go-to choice for precision devices like turning centers, lathes, and profile grinders. While rolled ball screws have increased in precision over the years, ground ball screws remain the best option for accuracy.

Even though you’ve learned about some of the applications of different types of ball screws, we can’t sum up a tool this versatile so briefly. Discover the uses of ball screws in the oil and gas industry and marvel at the capabilities of this incredible instrument!