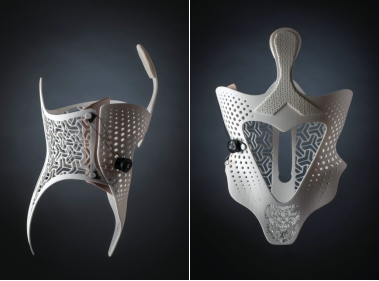

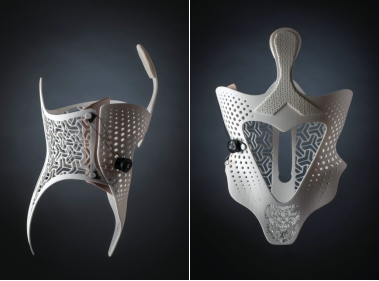

Sculpteo and Daniel Robert Ortopedic unveil the 1st eco-responsible, custom-made 3D printed orthopedic orthosis!

Sculpteo, a leader in 3D printing and digital manufacturing, announces a partnership with Daniel Robert Orthopedic, a leader in technical orthopedics. Thanks to 3D printing, the two companies are launching the first fully customizable orthosis made from a bio-sourced and recyclable material, PA11, made from castor oil. Light, breathable and flexible, this orthosis can face the most complex designs to adapt to the morphology of each patient. By collaborating with Daniel Robert Orthopédie, Sculpteo strengthens its position as a leader in 3D printing by rapidly producing orthotics and prostheses, unique, custom-made, and in quantity.

Unique devices offered by experts in orthopedics and 3D printing

Daniel Robert Orthopédie designs and manufactures fully individualized medical devices adapted to the needs of each patient. The company offers an unprecedented production quality: it surrounds itself with professionals specializing in ortho-prosthesis, podo-orthopedics, and positioning means for patients in wheelchairs. While the global orthopedic market is estimated at 32 billion dollars per year, the Swiss specialist must increase the pace of production while still ensuring the best adaptation to the needs of each patient.

By partnering with Sculpteo, the company has access to a responsive platform to place orders in large quantities quickly and competitively. Moreover, 3D printing makes it easy to reproduce a prosthesis or adapt it to the patients, such as children’s orthoses, which must be replaced often with different sizes but with the same functionality and structure. By offering complex design opportunities, the devices can thus cover a variety of pathologies (scoliosis, hemiplegia, amputations, cerebral palsy, plagiocephaly) for patients of all ages.

According to Daniel Robert, ortho prosthesis and director, “Sculpteo has become an important partner in the development of 3D printing. The technologies offered by Sculpteo help us choose the right processes for the different applications. Chemical treatments for finishes are a big plus. The platform is very responsive and allows us to order quickly.”

* PA11: A bio-derived, flexible, and ultra-resistant material

For the first time, orthopedic products are made with Polyamide 11 (PA11): a 100% bio-sourced, renewable polymer made from castor beans – unlike Polyamide 12, made from petroleum materials. PA11 is flexible, “more breathable” for the patient’s body, and offers ideal mechanical properties for this use.

It is a powder-based technology; the surface finish is uniform and smooth, with no visible layers. Available in white in its raw form (SLS technology) and black (Multi Jet Fusion technology), PA11 is a versatile polymer with excellent mechanical properties. Both SLS and Multi Jet Fusion PA11 technologies offer various finishing options from dyeing to chemical smoothing, giving the parts the quality and aesthetics of injection molded plastics. The material is SO 10993 & USP Biocompatibility certified.

In addition, there is no problem with supply, and the use of this material makes it possible to support India, one of the wealthiest countries in castor beans, with Brazil and China representing nearly 70% of the world supply.

According to Clément Moreau, CEO and co-founder of Sculpteo, “We launched 3D printing in PA 11 to enable our partners to develop 100% tailor-made products in record time and at an advantageous cost while maintaining the ecological approach that is close to our hearts. Together, we offer orthoses & prostheses able to evolve according to the needs of their users, which will revolutionize the lives of millions of people.”

About Sculpteo

Sculpteo, a pioneer and specialist in digital manufacturing, offers an online 3D printing service. Sculpteo provides an online platform to securely upload 3D files and select from over 75 materials and finishing options. Professional engineers and technicians produce parts using industrial 3D printing technologies before sending them to businesses and individuals worldwide. The company is based in Paris and San Francisco,

Sculpteo offers large-scale 3D printing and manufacturing for start-ups, SMEs, and design studios. Sculpteo offers its professional 3D printing service alongside its expert Design studio to help companies integrate additive manufacturing into their development and production processes. Sculpteo was created in 2009 by Eric Carreel and Clément Moreau and acquired by BASF New Business GmbH in November 2019.

About BASF 3D Printing Solutions

BASF 3D Printing Solutions Gmbh, headquartered in Heidelberg, Germany, is a subsidiary of BASF New Business Gmbh. BASF 3D Printing Solutions Gmbh focuses on establishing and expanding the business with 3D printing materials, system solutions, components, and services. BASF 3DPS is organized into start-ups to serve its customers in the dynamic 3D printing market. It cooperates closely with global research platforms and application technology experts from various BASF departments and with leading research institutes, universities, start-ups, and industrial partners. Potential customers are primarily companies that intend to use 3D printing for industrial manufacturing, typically in the automotive, aerospace, and consumer goods industries.

More information: www.sculpteo.com

About Daniel Robert Orthopédie SA

Founded in Switzerland, Daniel Robert Orthopédie offers comprehensive services in technical orthopedics, orthotics, prostheses, rehabilitation positioning, and special shoes. The company has professionals specializing in ortho-prosthesis, podo-orthopedics, and in seat positioning.

The company is expanding to offer more 3D solutions for orthotics and prosthetics through OrthoVoxel®. Daniel Robert, an orthosis and prosthetist practitioner in Switzerland, is also launching this new service to provide global 3D printing solutions to his peers. These professionals wish to become more involved in O&P 3D printing.

More information: www.orthovoxel.com