LUNAZ CONFIRMS FIRST ELECTRIFIED ASTON MARTIN DB6 BOUND FOR USA

“The DB6 represents the final evolution of Aston Martin’s legendary dynasty of thoroughbred GT cars from the 1960s; indeed, many enthusiasts today still consider it ‘the last real Aston’. In upcycling this beautiful example to fully electric power, we’ve given a new lease of life to one of the world’s most desirable and historically important cars – a mission that is resonating with a rapidly expanding number of customers in the United States. Just as importantly, our process and technology have allowed the owner to configure the car exactly as she wants it, and enjoy an authentic classic car experience entirely on her own terms. That makes this car a very special and satisfying commission, and a clear statement of intent from America’s super-luxury consumers.”

David Lorenz, Founder, Lunaz

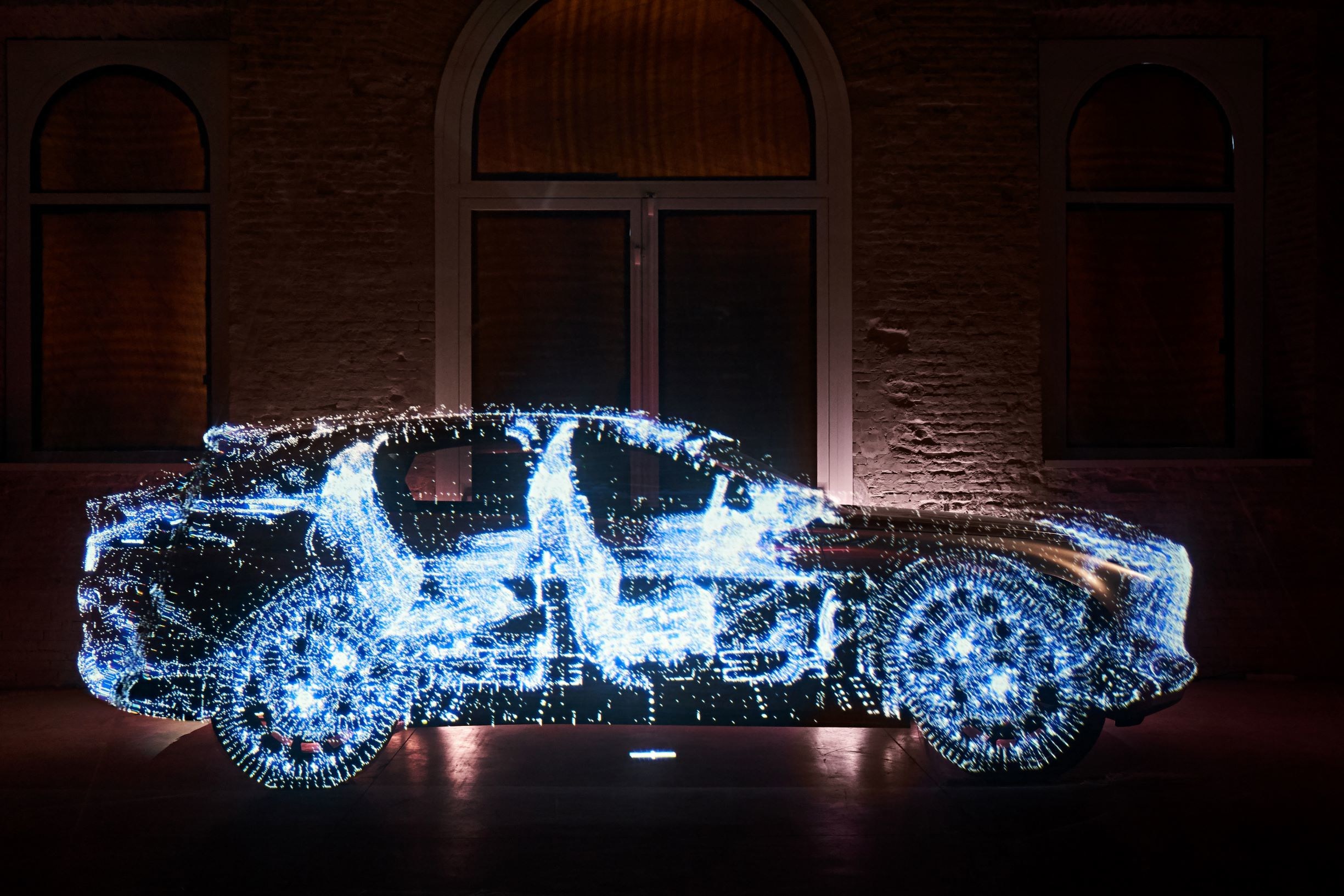

Lunaz confirms the final configuration of its first fully electrified Aston Martin DB6 by Lunaz Design bound for the USA.

The car, one of fewer than 1,800 made between 1965 and 1970, will be fully restored and upcycled at the Lunaz research and production facility, the first of its kind in the world, at Silverstone, UK. It is the latest in a series of commissions involving the electrification of cars from marques including Rolls-Royce, Bentley, Jaguar and Range Rover.

Lunaz Design’s focus on British marques has resonated with a rapidly growing customer base in the United States of America. While Lunaz has attracted clients from the country’s established economic powerhouses – the east and west costs by way of New York and California – demand has surged in Miami, Florida, where an emergent group of young ultra-high-net-worth individuals are compelled by Lunaz’ upcycled offering. Indeed, around 30% of Aston Martin DB6 by Lunaz build slots are currently allocated to customers from Miami and the surrounding area.

A new aesthetic language

The design concept for the first American Aston Martin DB6 by Lunaz is ‘Evergreen’, referencing both the timeless beauty and appeal of the DB6, and the environmental credentials of the Lunaz upcycling process and all-electric powertrain.

The exterior features a unique black-green paint finish, complemented by the interior in dark green leather. Orange accents on the seats, running longitudinally, reflect the stroboscopic effect of overhead motorway lighting, recalling the owner’s late-night drives between her inland office and weekend retreat in Miami Beach. Indeed, the interior introduces a sophisticated neutral colour palette to a car with traditionally masculine associations.

A grand dream realised

The car is the fulfilment of a long-held ambition for the owner. For years she had been captivated by the glamour and elegance of the sixties, automotive design’s golden age, but was deterred by the practical realities of classic-car ownership. She also found it impossible to reconcile her keen interest in environmental issues with the lower fuel efficiency and higher emissions inherent to older petrol-engined cars.

Unsatisfied by the existing crop of EVs, upcycling offered her the ideal solution. The Aston Martin DB6 by Lunaz represents the best of all worlds: an authentic classic car that is exhilarating yet serene, combining engaging driving with effortless ownership.

Reflecting the client’s affinity with no-compromise sustainability, her Aston Martin DB6 by Lunaz will be provisioned with carpets made from recycled fishing nets recovered from the ocean, which match the finish of lambswool. Cactus leather will be used throughout the vehicle in place of animal products, highlighted with woven hemp inserts.

Classic Aston Martin performance reimagined

Since configuration of the client’s Aston Martin DB6 by Lunaz has been confirmed, it will undergo an exhaustive bare-metal restoration and re-engineering process to concourse standards.

Driveability is ensured through the up-rating of brakes, suspension and steering while interior comfort and convenience is brought up to modern standards through the provision of air conditioning and the sensitive integration of latest infotainment, navigation systems and full Wi-Fi connectivity.

The car will be powered by Lunaz’ proprietary modular electric powertrain, developed entirely in-house and comprised of the very highest standard European-sourced Tier 1 OEM battery cells and motors. All current Lunaz vehicles’ battery capacity ranges from 80-120 kWh. Range is 180-250 miles. Every car by Lunaz is equipped with CCS fast-charging capability.

The final tune of this particular DB6 will be undertaken in close collaboration with the client, however the Lunaz powertrain is capable of producing 375bhp and 516lb ft of torque.

The Lunaz upcycling process

The DB6 donor car will undergo a proven process that ensures it meets Lunaz’s three key requirements for an upcycled electric vehicle: usability, reliability and sustainability.

It begins with a detailed inspection and assessment to determine the chassis, powertrain and suspension configurations. Lunaz engineers use 3D scanning to create detailed CAD models as the basis for any renovation and reconstruction work required.

The car body is then stripped down to a bare metal shell and returned to as-new condition using traditional coachbuilding and restoration techniques. Any external and internal plastics are repaired and recoated: anything that can’t be reused, down to the nylon in the seatbelt cord, is recycled.

The internal combustion engine and its associated systems, lubricants and other fluids are carefully removed and reclaimed, then replaced with Lunaz’s proprietary fully-electric powertrain. The modular design, developed entirely in-house, allows engineers to adjust individual components to perfectly reflect the car’s innate character, and the owner’s personal preferences. The battery cells, inverters and motors are all original equipment made to Lunaz’s specification by top European Tier 1 suppliers.

Other vital systems, including brakes, steering, suspension and electrics, are all given Lunaz’s ‘full modernisation’ treatment to bring them into line with current safety standards and driver expectations.

Aston Martin DB6

Unveiled at the 1965 London Motor Show, the DB6 was an evolution of the DB4 and DB5, the latter famously driven by James Bond; the most noticeable design change was the Kamm tail rear spoiler, designed to improve stability at high speed. Slightly longer and taller than its predecessors, the DB6’s improved headroom and legroom for rear-seat passengers made it a somewhat more practical proposition, without compromising its essential GT looks and character.

Notable owners included Paul McCartney, Mick Jagger, model and singer Twiggy, and actor and comedian Peter Sellers. King Charles III still owns the rare DB6-based Volante MkII convertible variant he was given by the late Queen on his 21st birthday.

In its original form, the DB6 sported a DOHC straight-six, 3995 cc engine developing 282 bhp and capable of reaching 0-60 mph in 8.4 seconds and a top speed of 150mph.

THE EXPANDED LUNAZ GROUP:

The Lunaz Group remanufactures and electrifies passenger, commercial and industrial vehicles through three distinct companies:

Lunaz Design: Revives, re-engineers and converts pinnacle classic cars to electric powertrains.

Lunaz Applied Technologies: Upcycles and re-engineers specialist industrial fleet vehicles to factory new standard and converts them to the Lunaz proprietary electric powertrain.

Lunaz Powertrain: Provides the Lunaz proprietary modular powertrain as a turn-key, white-label product for OEMs, Tier 1 suppliers and independent automotive engineering businesses.

Lunaz was founded in 2018 and, following the launch of the world’s first electric Bentley, Rolls-Royce, Range Rover and Jaguar sportscars, secured growth capital investment in 2021 from leading institutional names including: the Barclay, Reuben and Dallal families as well as David Beckham.

GLOBAL SUCCESS, ANCHORED IN THE UNITED KINGDOM:

“The growth of the Lunaz Group affirms the United Kingdom’s status as a leader in the development of clean-air automotive technologies. Firms like Lunaz which operate in the principles of the circular economy show that British industry can provide potent answers to the global need to transition to less impactful industrial practices.”

David Lorenz, Founder, Lunaz Group

The Lunaz Group has committed long-term to Britain and specifically Silverstone as its global HQ. This reflects the United Kingdom’s standing as a leader in the development of electric powertrains.

From this global R&D and Technical HQ, the Lunaz Group will manage a network of manufacturing facilities placed in proximity to its major global markets. The company is already in discussions with European governments seeking to attract fast-growth clean-technology engineering businesses.

North America is also firmly in the company’s sights with advanced discussions underway with States seeking to build long-term clean tech jobs growth.

ABOUT THE FOUNDERS: DAVID LORENZ

After the successful exit from his last business, David Lorenz sought to address the potential mass-redundancy of the 2 billion ICE vehicles that currently exist on the planet. Lunaz is his answer.

From these foundations Lorenz has strategically driven one of the fastest growing clean-technology businesses in the United Kingdom. In doing so he has inspired some of the country’s most decorated and celebrated engineers and technical minds to join him in creating a modular and proprietary clean-air powertrain.

This will be the foundation for driving Lorenz’s vision to remanufacture and electrify passenger, commercial and industrial vehicles of all sizes and specifications as a solution to the global drive towards decarbonisation.

Lorenz is married with one daughter, Luna who the company is named after.

ABOUT THE FOUNDERS: JON HILTON

The Lunaz Group Managing Director and Technical Lead is among the most highly regarded technical minds in his field. He built his reputation as Technical Director for Renault F1 winning Fernando Alonso’s successive World Championships.

Hilton’s career started by engineering the powertrains for a successful helicopter world speed record at Rolls-Royce PLC. He then moved to the development of powertrains for motorsport.

Hilton later founded his hybrid powertrains company to exploit the potential of applications beyond F1 by the introduction of new Kinetic Recovery Systems (KERS). It was here that he engineered pioneering hybrid powertrain conversions for performance passenger cars and industrial vehicles.

While developing this cutting-edge clean-air technology, Hilton also technically directed the first ever hybrid Le Mans entry for Hope Polevision Racing sparking a passion for alternative powertrains.