Chart Recorder Maintenance: Repair or Replace?

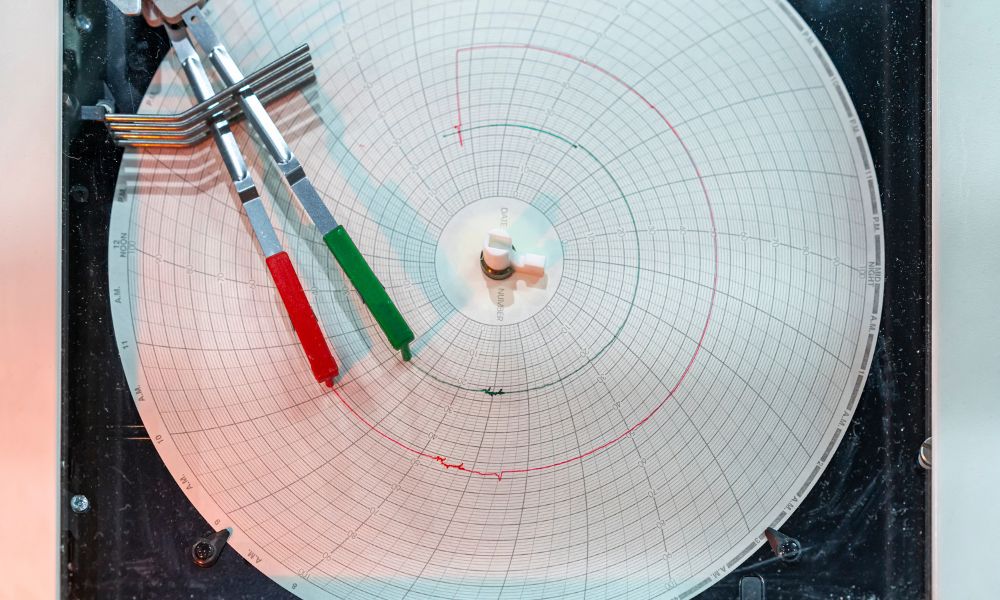

Chart recorders are vital tools for various industries, from manufacturing and pharmaceuticals to power generation and food processing. These devices provide a graphical representation of specific variables over time, such as temperature, pressure, voltage, or humidity. This data is essential for monitoring system performance, ensuring regulatory compliance, and optimizing process efficiency.

However, a damaged or poorly maintained chart recorder can lead to inaccurate readings, severely impacting operational efficiency, product quality, safety, and even regulatory compliance in certain industries. Therefore, understanding when to repair or replace a damaged chart recorder is paramount.

When To Repair

When maintaining a chart recorder, you’ll find situations in which repair is the most practical solution. For instance, if you’re dealing with minor issues like a malfunctioning pen arm, a jammed paper feed, or an unresponsive display panel, a simple repair often fixes the problem. If your recorder is relatively new and hasn’t suffered excessive wear and tear, repairing it can be more cost-effective than replacing it.

You can also rectify problems like inconsistent voltage from the power supply with a repair job. Moreover, if your chart recorder features specialized configurations to suit your specific industry requirements, opting for repair lets you preserve those unique specifications for a fraction of the replacement cost. Finally, you can capitalize on the importance of chart recorder calibration, a simple test that is typically all it takes to fix a faulty device! Consider these measures before opting for a total device replacement.

When To Replace

There are certainly situations when replacing a chart recorder is the most sensible decision. One such instance is when the device is old and has undergone numerous repairs, making it more prone to future breakdowns. In fact, regularly occurring malfunctions could indicate that the recorder’s lifespan is nearing its end.

Another situation warranting replacement is when the repair costs start exceeding a new unit’s price. Technological advancements can also necessitate a replacement. An upgrade might be in order if your current recorder lacks features that newer models offer, such as digital interfaces, remote access capabilities, or higher precision measurements. Lastly, if you’re dealing with obsolete models with spare parts that are hard to find or overly expensive, it’s undoubtedly time for a replacement.

Tips for Selecting a New Chart Recorder

When shopping for a new chart recorder, you must consider several factors. First, assess the specific needs of your operation. For instance, you need to determine whether you require a single-channel recorder or a multi-channel one based on the number of variables you need to monitor simultaneously.

Furthermore, don’t overlook the importance of durability and reliability. Ensure the recorder is from a reputable manufacturer and check customer reviews to gauge its performance and longevity. Considering these factors before purchasing your unit can significantly help you choose the ideal chart recorder device for your specific needs.

Navigating chart recorder maintenance can be complex, but understanding when to repair or replace your device undoubtedly simplifies the process. Regular maintenance and timely repairs will extend your recorder’s lifespan and ensure accurate data recording. However, when repair is no longer feasible, don’t hesitate to replace your chart recorder to maintain operational efficiency and data integrity.