NASA Helps Emerging Space Companies ‘Take the Heat’

Things are heating up in the atmosphere, and NASA is helping space start-ups stay cool.

NASA has decades of expertise in creating technology that protects spacecraft from the intense heat generated when entering an atmosphere. As emerging companies develop innovative ways to do business in space, they know where to turn – and the agency is responding by offering its know-how and the advanced materials invented here to help enable new uses for space with big benefits for humanity.

Since 1951, when Harvey Allen, an engineer at NASA’s Ames Research Center in California’s Silicon Valley, showed a blunt-shaped capsule helps deflect the heat of atmospheric entry, Ames has led the agency in designing, developing, and testing thermal protection systems (TPS). These heat shields protect re-entering spacecraft and their cargo, such as pieces of a 4.5-billion-year-old asteroid or astronauts who will travel in the Orion crew capsule.

“In the past, the government was the only entity that needed heat shields,” said David Hash, chief of the Entry Systems and Technology Division at Ames, “That’s changing dramatically today. Companies that see new opportunities for commercial activities in space now have a business case to launch spacecraft and bring them back to Earth. NASA is uniquely positioned to show them how to do it.”

NASA works to encourage commercial growth. With an increasing number of start-ups who have smart ideas but limited funding and spaceflight experience, NASA experts at Ames and Langley Research Center in Hampton, Virginia, are doing their part to help. And success is already in the air – or passing safely through it.

In the past, the government was the only entity that needed heat shields. That’s changing dramatically today.

DAVID HASH

Chief, Entry Systems and Technology Division, NASA’s Ames Research Center

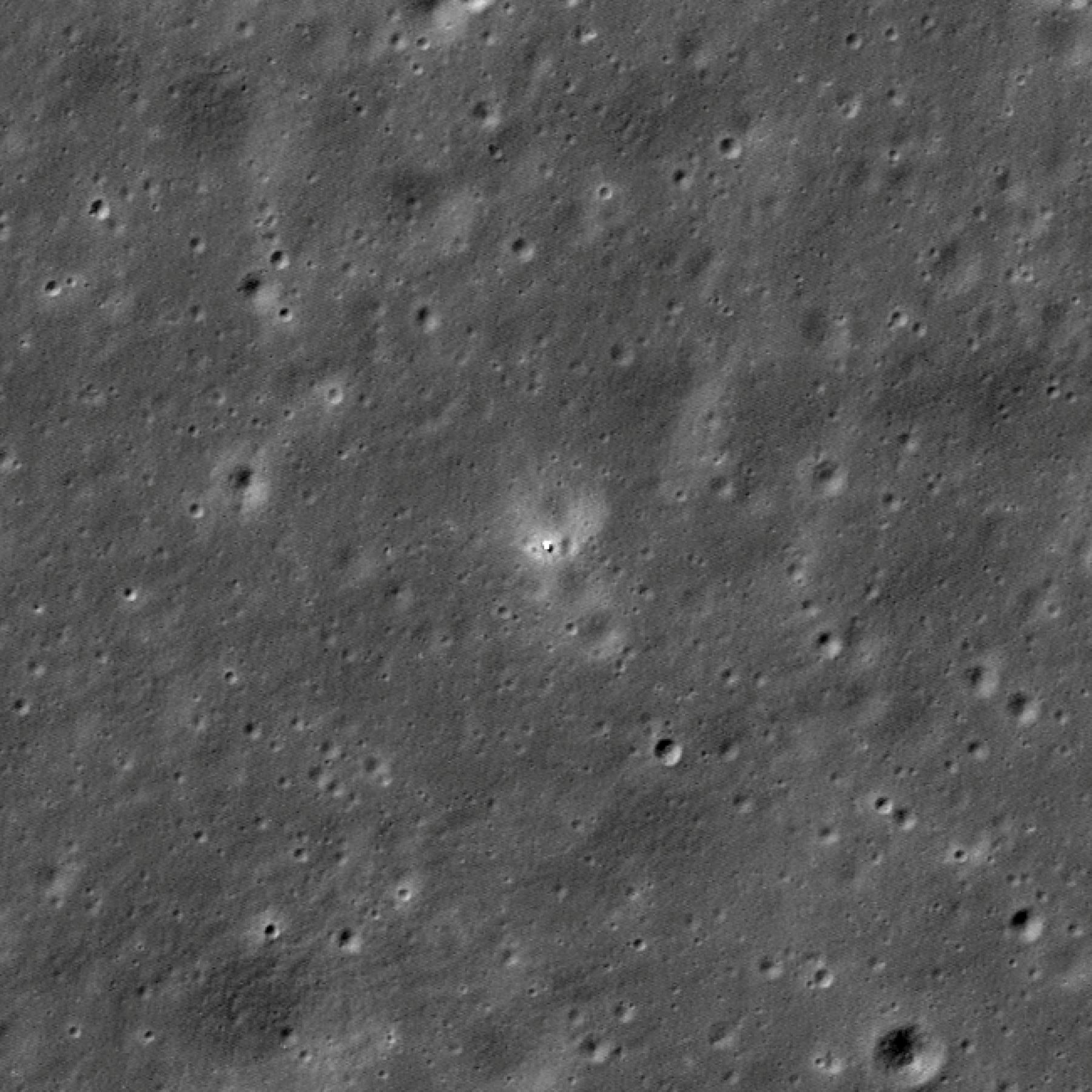

On Feb. 21, Varda Space Industries of El Segundo, California, in partnership with Rocket Lab USA of Long Beach, California, returned to Earth the first product processed on its autonomous, free-flying, in-space manufacturing platform. The product is a pharmaceutical that may gain unique properties by forming in the near-absence of gravity. Ames made the spacecraft’s heat shield material, and Langley assisted Varda in developing their re-entry capsule through aeroscience expertise, systems design and analysis, and trade studies support.

Through a partnership agreement, Ames produced the thermal protection material, called C-PICA (Conformal Phenolic Impregnated Carbon Ablator), intended to bring down products from Varda’s factory in orbit for its first four missions. The material was originally developed at Ames, and February’s re-entry marked the first time a NASA-manufactured C-PICA heat shield ever returned from space.

“We performed extensive testing on the ground, in our arc jet facilities, where we can simulate the high temperatures of entry,” said Mairead Stackpoole, chief of the Thermal Protection Materials Branch at Ames, “but there’s nothing like a real spaceflight to test our systems. The Ames TPS team will soon take samples from the heat shield to analyze its performance in detail.”

NASA’s partnership with Varda will continue through a Tipping Point award from the agency’s Space Technology Mission Directorate (STMD). Managed by STMD’s Flight Opportunities program, this award will leverage technology transfer from Ames of the C-PICA production process, helping the small business establish its heat shield production and fully enter the space market, as well as a flight test to evaluate the material’s performance. A joint effort between NASA, the Air Force Research Laboratory, and Varda will also provide more flight tests of C-PICA, helping to fully mature this technology relevant for future Mars missions and more.

NASA’s thermal protection experts can work with any space company on tackling the complex challenges of re-entry. Current collaborations include two companies targeting flights in the coming year.

A heat shield made by NASA is visible on the blunt, upward-facing side of a space capsule after its landing in the Utah desert. Varda Space Industries returned to Earth the first product processed on its in-space manufacturing platform on Feb. 21, 2024.

Varda Space Industries/John Kraus

The first flight of Inversion Space of Torrance, California, will take place in 2024 with the goal of using space to transport cargo. Inversion’s vehicle will re-enter the atmosphere using a C-PICA heat shield and a backshell, which protects the “downstream” end of the vehicle, made of another material developed at Ames: silicone-infused refractory ceramic ablator (SIRCA).

Later, NASA will support the first private mission to Venus with Rocket Lab. The spacecraft will use NASA’s Heatshield for Extreme Entry Environment Technology, developed at Ames, and a SIRCA backshell.

These and other projects NASA is enabling are born of 21st-century innovation, yet Hash sees similarities with the formation of commercial airlines in the 1920s and 30s.

As the Smithsonian’s National Postal Museum explains, when Congress passed the Air Mail Act in 1925, it allowed the U.S. Postal Service to transport mail using commercial air carriers. Because companies could not rely on paying passengers in the early years to survive, this government participation encouraged and enabled the development of commercial aviation. NASA’s predecessor, the National Advisory Committee for Aeronautics, had the important role of advancing technologies to enable this new market.

“We need to do the same thing they did for the airways, only for the spaceways,” said Hash. “That’s our job, now. It’s the perfect role for government, and it will increase economic prosperity for our country.”

For news media:

Members of the news media interested in covering this topic should reach out to the NASA Ames newsroom.