iButton ™: Making Technology Wearable

A Simple Solution to a Common Problem

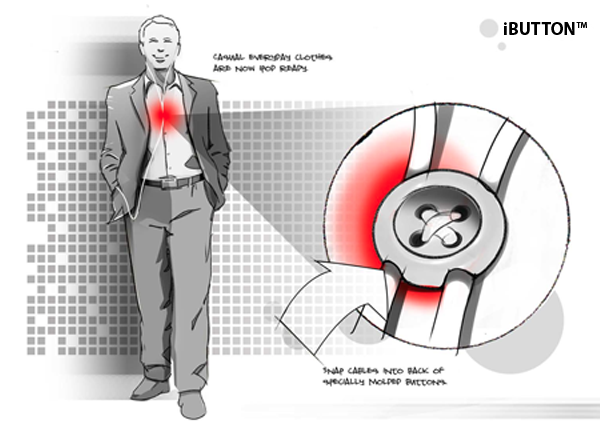

Everyone knows the frustrations of using earbud cords. The cord sometimes has a mind of its own and gets caught or tangled just when it’s least expected. We’ve devised a way to simply pop your earbud cord into convenient grooves embedded in the buttons on your shirt or sweater.

Keep your earbud cord held close to your body

This means you no longer need to shimmy the earbud cord down your shirt. You can now keep your earbud cord outside your garments without losing the convenience of keeping the cord under control.

Keep your earbuds from dropping to your toes

When you remove your earbuds from your ears, iButton™ keeps the cord held tight so you can let them dangle without them dropping to the floor, leaving your hands are free for other tasks.

Keep the cord from getting caught on passing objects

Nothing’s more annoying that your earbuds getting yanked from your ears when the cord catches on some nearby object.

Easy to sew on!

We’ll tell you a little secret. Replacing a button is easy! Anyone can do it. Here’s a quick tutorial. iButtons™ are a quick and easy way to add new functionality to your garments.

Fits almost all round earbud cords

Nearly all round earbud cords are the same diameter, so iButtons™ will fit most major brand earbud cords.

Made in three standard sizes

Great for shirts, sweaters, jackets and any garment that uses buttons.

Why we need your help

Our goal is to get iButton™, as a packaged product, into the thousands of craft stores around the country. Retailers like: Michael’s Art Supply (1500 stores) and JoAnn Fabrics (750 stores). These are retailers with customers for whom picking up a needle and thread to sew on a button is second nature.

The really big job of this project is completed. The patent! We hold an issued patent on this concept (US 8,539,649 B2). Now we need to cut production molds for the parts, design packaging and create point-of-purchase displays for stores. Once we have this finished we can start approaching all the big art and craft store chains with a compelling product offering.

Stretch Goals

We would like to do as many sizes and colors as possible, but each color adds a minimum run of product at the factory. At our $6000 goal we will produce 3 sizes in black and white.

At $20,000 we’ll add primary colors (red, yellow, blue).

At $40,000 we’ll add more colors (purple, green, orange).

At $60,000 we’ll add translucent and Kickstarter green.

Packaging/Rewards

This is a rough representation of packaging and how we’ll deliver your Kickstarter rewards. The 19mm and 15mm buttons will come in packs of two, and the 11mm standard dress shirt size buttons will come in packs of three. Only one color will be in a pack, and you only need to replace one button on a shirt (usually the second to the top button).

Think about how many shirts your family has in various closets around the house when considering how many and what color iButtons™ to get.

Depending on what the design firm comes up with, the packaging layout may change, but the package quantities will remain as shown above.

Production Schedule

Here’s a rough estimate of how the rest of the project should run after the completion of a successful Kickstarter campaign. Some of these items could go faster or slower than presented here. I believe we’re leaving ample room for a few potential setbacks, if any come up.

Risks and challengesLearn about accountability on Kickstarter

This is a fairly low risk project. The product is extremely simple. The molding is not complex. The patent is complete. We already have a factory to do the work. There’s no complex assembly of parts associated with this product, and thus no long lead time components that can delay a project. If we were to get a large number of backers for this project, then we’d have to look at fulfillment houses to ship the orders. But that’s pretty standard work too.

I’m sorry but I’m having a hard time thinking of many things that could go wrong with this project. Okay, if I get hit by a bus there may be an extended delay. But, I promise, once I come out of my coma we’re straight back to work! 🙂