The Different Machines in a Metal Fabrication Shop

Many industries rely on the supplies they get from metal fabrication shops. For example, automotive workers would not be able to construct a vehicle without the materials produced by fabricators. But metalworkers do not do all the work by themselves. Instead, there are many different machines in a metal fabrication shop that help them complete their projects.

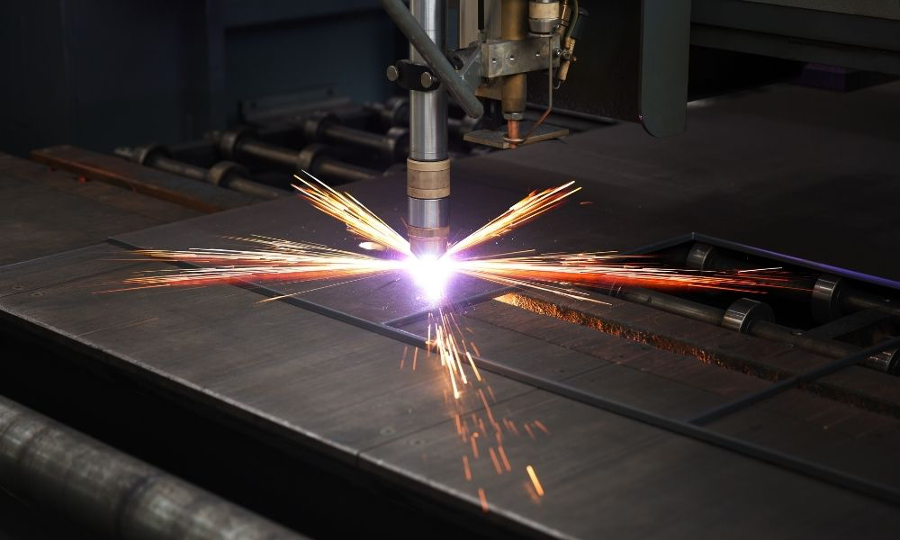

Plasma Cutters

Plasma cutters help fabricators cut through thick material like sheet metal. These devices use a high-powered laser to cut through material that would be impossible to do by hand. However, accidents can occur if workers do not use these machines as intended. As a result, supervisors must set up top-of-the-line training programs to ensure that everyone knows how to use these devices. Moreover, shop managers must keep specifications in mind so that they choose the right plasma cutter for their shop.

Shears

Metal shears are far less advanced than plasma cutters. Still, they are a useful tool to have in the shop. Unlike plasma cutters, shears do not use a laser to cut through materials. Rather, the tools function like sharp scissors that fabricators can use to make a quick cut. Shears are great for rapid jobs because they require less setup time than machines. In addition, metal shears can be less dangerous than laser-powered machines because metalworkers do not have to worry about getting burned.

Automated Deburring Devices

The final step in the metal fabrication process is deburring. Shop managers should invest in automated deburring and finishing machines so that each project is fully completed. Deburring devices get rid of any unwanted markings or cracks that are left on the metal. Fabricators can do these things by hand, but it takes a large amount of time. Managers should purchase these tools to increase efficiency in the workplace.

This article has described the different machines in a metal fabrication shop. Without these devices, workers would have to complete strenuous projects by hand. Not only is this more dangerous, but tasks will take longer to finish. Business owners who value productivity should invest in these machines.