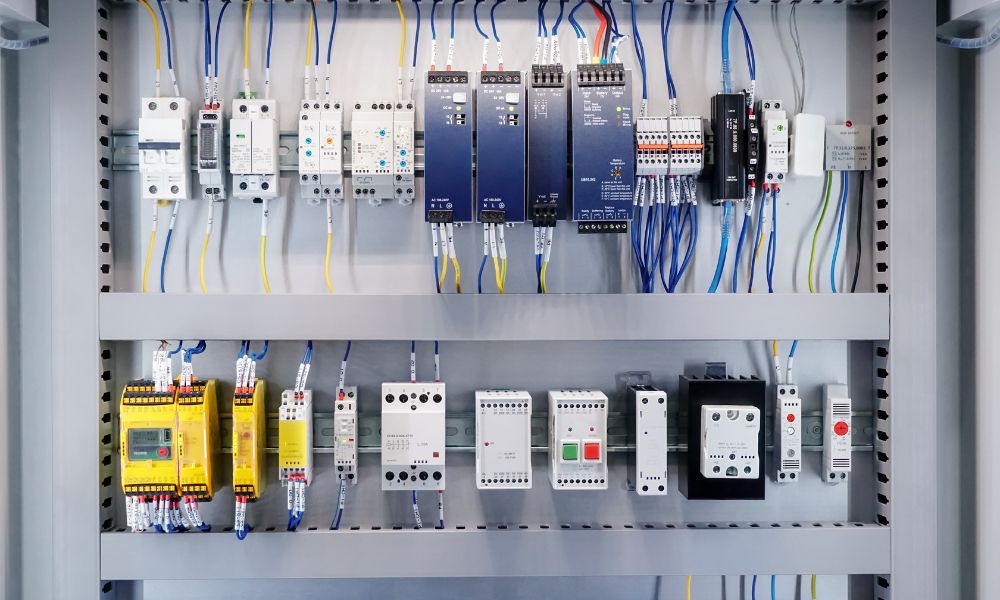

At the heart of every major production line is an intricate electrical engineering system orchestrating the rhythm of manufacturing life. If a factory is a modern Colosseum of industry, then an electrical control panel—a seemingly inconspicuous metallic cabinet—houses the technological gladiators that carry out various functions.

Let’s look at the benefits of an industrial electrical control panel and why it’s an essential component in any manufacturing process.

Increased Efficiency

One of the main benefits of having an industrial electrical control panel is the increased efficiency it brings to a production line. Automating processes and controlling equipment through a centralized system greatly reduces the need for manual labor and human error.

Furthermore, with the ability to program and monitor all operations from one location, production can run smoothly without any delays or interruptions. This production leads to higher productivity and, ultimately, increased profits for the company.

Improved Safety

Safety is a top priority in any industrial setting, and an electrical control panel is crucial. By centralizing all controls, workers are less likely to contact live wires or hazardous equipment directly.

Moreover, modern industrial control panels have advanced safety features, such as emergency stop buttons and fault detection systems. These features protect workers and prevent equipment damage and costly downtime.

Cost Savings

In addition to improving efficiency, an industrial electrical control panel can significantly reduce operating costs for a company. Businesses can save on labor costs by streamlining processes and reducing the need for manual labor.

Moreover, with advanced energy management capabilities, control panels can optimize power usage and reduce energy consumption. This reduction leads to cost savings in utility bills and contributes to a company’s sustainability efforts.

Remote Monitoring and Troubleshooting

Another benefit of modern industrial control panels is the ability to monitor and troubleshoot equipment remotely. With remote access technologies, engineers can monitor processes and detect potential issues in real time.

This monitoring allows prompt responses and troubleshooting, preventing costly breakdowns or production delays. Occasionally, you can resolve these issues remotely, saving time and resources.

Scalability

Industrial control panels are scalable, meaning they can adapt to the changing needs of a production line. As businesses grow and expand their operations, they can easily modify and upgrade their control panels to accommodate new equipment and processes. This modification eliminates the need to invest in a completely new control system, saving both time and money for the company.

Industrial electrical control panels not only serve as the brains of production lines but also offer numerous benefits that contribute to the overall success of a business. Learning how to get the most out of your industrial control panel and regularly maintaining it can help optimize operations and drive growth for your company. So invest in a high-quality control panel and keep it running at its best for maximum efficiency, safety, and cost savings.