Station Science Top News: Dec. 13, 2024

Benchmarks for solidifying metal alloys

Researchers report benchmark data for modeling the growth of specific types of microstructures that form during solidification of metal alloys under different conditions. These microstructures affect the properties of materials and products such as refrigeration devices and solar cells.

The ESA (European Space Agency) Columnar-to-Equiaxed Transition in Solidification Processing (CETSOL) investigation studied the processes of metal alloy solidification and the crystal patterns that form as liquids transition to solids. Results could improve ground-based development of lightweight, high-performance structural materials for space and ground applications. Microgravity is key to this research because it eliminates influences of gravity during solidification and allows researchers to control turbulence and convection.

European Space Agency (ESA) astronaut Frank De Winne works on the Columnar-to-Equiaxed Transition in Solidification Processing (CETSOL) investigation in the U.S. Destiny Laboratory.

NASA

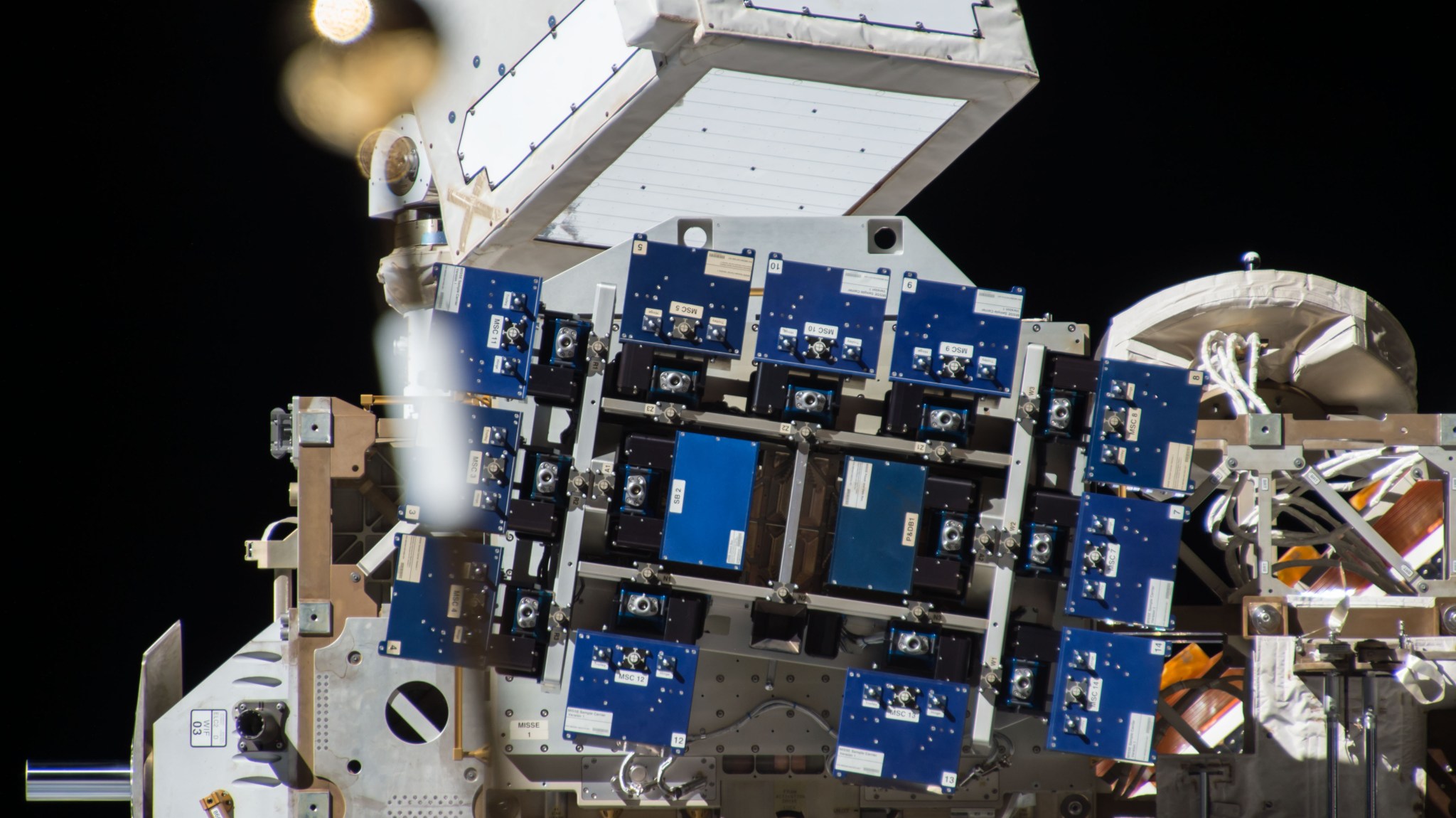

Composite materials shield against radiation, other hazards

Researchers found no degradation in two multifunctional radiation shielding composite materials after exposure to space. This finding suggests that composite materials with a surface layer and a coating could protect crews on future missions from radiation and other hazards of space.

Materials ISS Experiment Flight Facility (MISSE-FF) continued a series of investigations examining how exposure to space affects materials and material configurations used for space missions. The MISSE-13 suite of materials included a multifunctional composite material for shielding crew members in habitats and spacecraft beyond low Earth orbit against radiation, atomic oxygen, and temperature extremes.

An image of the Materials ISS Experiment Flight Facility (MISSE-FF) platform used for MISSE experiments.

NASA

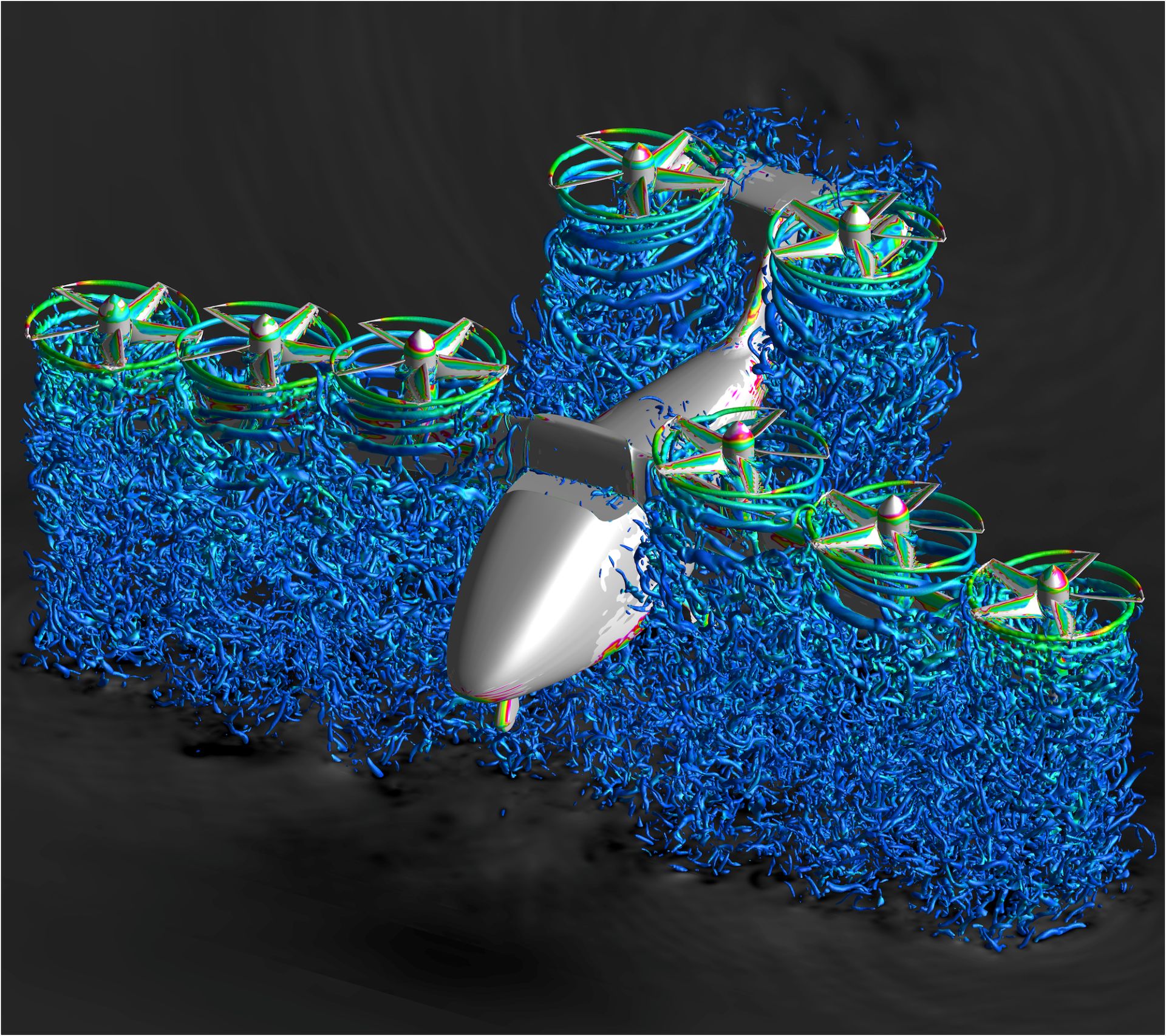

Modeling the use of boiling to transfer heat

Researchers developed an algorithm to determine the amount of heat transferred via boiling of a liquid and showed that maximum heat flow occurs where the bubble contacts the surface and the liquid. This finding could inform design of thermal control systems for spacecraft and for cooling electronics and other applications on Earth.

ESA’s Multiscale Boiling examined the dynamics of heat transfer via boiling, which generates vapor bubbles that lift heat from a surface. This technique is less efficient in microgravity because boiling happens more slowly, and bubbles remain near the surface in the absence of buoyancy. But microgravity also makes it possible to observe effects that are too fast and too small to be measured under normal gravity conditions, helping scientists understand the dynamics of boiling heat transfer.

ESA astronaut Luca Parmitano works on the Multiscale Boiling hardware aboard the International Space Station.

ESA/Luca Parmitano